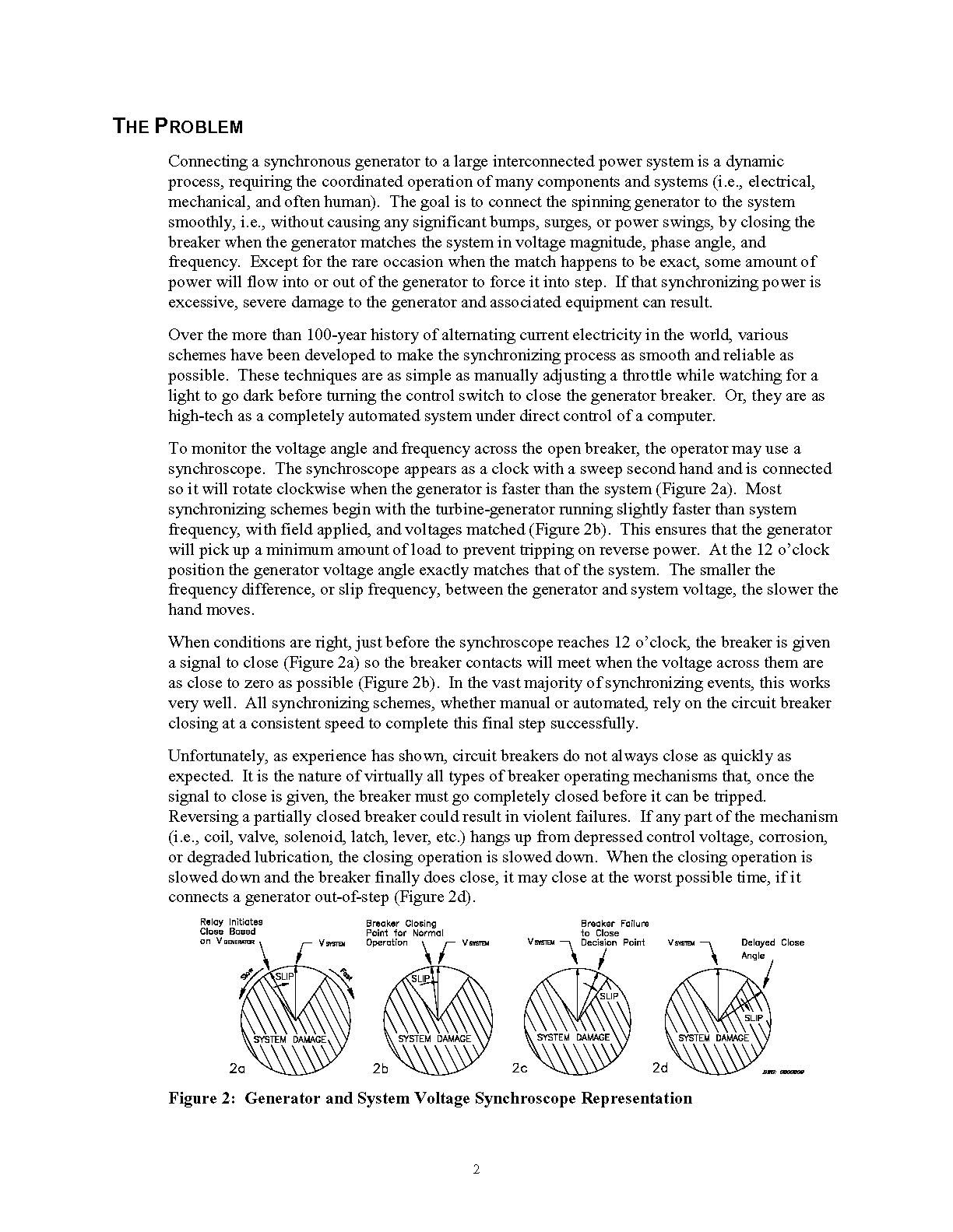

All generators have to be synchronized before their connection to the bussbar

SKU 552060

-High quality and reliable

-Compact Design

-Easy start and maintenance

-Enclosures available

-Subject to a comprehensive test program which includes full and overload

testing and proving of all control and safety shut down functions.

Deep Sea Control Panel 5210

Model 5210 is an Automatic Engine Control Module. The module is used to

automatically start and stop the engine, indicating the operational status and

fault conditions, automatically shutting down the engine and indicating an

engine failure by means of an LCD display and an appropriate flashing LED on the

front panel. Selected timers and alarms can be altered by the customer from the

front panel. Alterations to the system are made using the

810 interface and a

PC. This interface also provides real-time diagnostic facilities.

It is possible to monitor operation of the system either locally or remotely. (Optional: remote communications output versions only.)

5210 Easy Pushbutton Control

Operation of the module is via pushbutton controls (with security locking

facility) mounted on the front panel with STOP/RESET, AUTO, MANUAL, and START

buttons. The first three buttons feature LED ‘selected’ indications. Further

buttons provide LCD DISPLAY SCROLL and EVENT LOG VIEW functions.

5210 Microprocessor Control

The module features 16 bit microprocessor control and a comprehensive list of

timers and pre-configured sequences. This allows demanding specifications to be

achieved. Configurable expansion facilities are also provided.

5210 Metering

The 5210 module provides metering via the LCD display with the following

instrumentation displays, accessed via the LCD DISPLAY SCROLL push buttons:

- Generator Volts L1-N, L2-N, L3-N

- Generator Volts L1-L2, L2-L3, L3-L1

- Generator Amps L1, L2, L3

- Generator Frequency Hz

- Engine Speed RPM

- Engine Oil Pressure

- Fuel Level %

- Engine Temperature

- Plant Battery Volts

- Engine Hours Run

- Generator kVA

- Generator kW

Specifications may vary. Confirm full specs prior to

ordering.

Accessories for Generators

Algae-X Fuel Conditioner/Filters

Base Tanks - Custom

Base Tanks - Stocked

Batteries

Battery Chargers

Control Panels

Enclosures

Fuel Tanks

Light Towers

Load Banks

Marathon Generator Ends

PTO Generators

Racor Fuel Filters

Remote Tanks

Trailers

-24000

lb Heavy Duty Trailer with Internal Fuel Tank

Transfer Switches

Transformers

Voltage Regulators

FOB Miami

In Stock

|

|

|

|

|

|

|

|

|

|

http://wanclik.free.fr/synchronization.htm

|

|

http://wanclik.free.fr/deif_synchro.htm

|

| 4400 x 1758x2267 mm | |||||||

| 1 MVA 400 v 60 HZ | 1500 Amps 400 V | 100 Amps 6 kV 25 meters |  |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

| PLC QUANTUM and SYNCRONIZATION PANEL | QUANTUM PROCESSOR | 7 CELLS SWITCHGEAR 6 KV |

|

|

http://wanclik.free.fr/applicom.htm

|

ProWORX 32™ V2.0 Programming SoftwareThe simply smart choice for 984 Ladder Logic customers Schneider Electric’s new ProWORX™ 32 V2.0 is the latest generation 984 Ladder Logic programming software. It offers a comprehensive suite of PLC programming and configuration tools, providing everything an engineer needs to design, configure, test and complete 984LL systems. Flexible and easy-to-use, ProWORX 32 gives 984LL users the power to program our Modicon® range of PLCs on-line or off-line, manage I/O subsystems, and analyze the plant’s activity in real-time, all in a familiar Windows® environment. Maximizing productivity and reliability ProWORX 32 software provides a highly functional set of features designed to maximize the productivity of your development and maintenance resources, as well as the reliability of your control systems:

|

||||||||||||||||

|

> IT-CO-FE > Services > OPC > Recommended tools > OPC Servers > OFS |

![]()

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|